|

|

| MAGNA - SWIFT, EASY AND ECONOMIC |

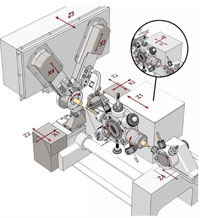

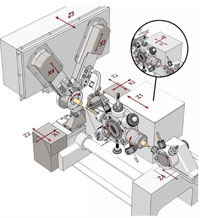

The MAGNA model is a very appropriate lathe for general purpose screw cutting of small parts and soft-medium materials. Its capability of working with up to 5 tools simultaneously and its ground configuration about transverse slides/front turret enable MAGNA to be a very adequate model to finish both ends of nearly all screw cutting parts up to 36 mm diameter, taking short cycle times and resulting a very profitable purchase for the operator.

This machine is designed for long or short series production due to its conversational-quick programming CNC system and the possibility of using commercial machining tools, which can be used on all its slides/turret by CNC interpolated machining.

In addition, it requires a minimum workshop area, only 2100 x 1400 mm (without bar loader).

|

| |

|

|

| Bar Passage with DIN 6343 collet (mm) | Ø16 | Ø26 | Ø36 |

| Main spindle motor: Asynchronous vectorial: | 5,5 kW |

| Maximum spindle speed (RPM) | 8.500 | 6.000 | 4.500 |

| Maximum Turning travel | 130 mm |

|

|

|

| 2 horizontal transverse slides (X,Z axes) |

| 2 vertical transverse slides (X axis. Z optional) |

| Bidirectional CNC main turret with 4 stations 1 1/4" and 4 stations VDI-20 with through-tool cooling (Z axis. X optional) |

| CNC Driven tools (1,3 kW) |

| Pick-up for second operations (optional) |

| Second operations up to 3 tools (optional) |

|

|

|

| C axis for the main spindle |

| Stop and lock of main spindle |

| Stop and lock of pick-up |

| Transverse drilling/ milling/ tapping device |

| Polygon turning/ thread milling device |

|

|

|

| MUPEM (conversational) |

| FAGOR (ISO language - C Axis optional) |

|

|

|