|

|

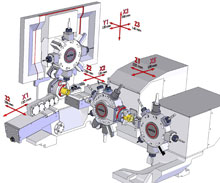

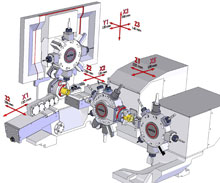

| WIN2 SERIES - STURDINESS Y PRODUCTIVITY |

New TWIN2 combines the capabilities of a sturdy lathe for screw cutting, with long travels and a milling machine which can work on the main spindel. It consists of a turret with 8 stations (4 of them can be live) and Y axis.

It is an essential machine to work with complex parts especially when dealing with hard materials and large diameters. Having a maximum turning travel of 250 mm and Z axis travel of 320 mm of the main turret it is suitable for long or small series of different kind of parts.

|

| |

|

|

| Bar Passage with DIN 6343 collet (mm) | Ø42 | Ø60 (65) | Ø80 | Ø100 |

| Main spindle motor: Asynchronous vectorial: | 11-15 kW | 15-18 kW | 18-22 kW |

| Maximum spindle speed (RPM) | 4.500 | 3.500 | 3.000 | 2.000 |

| Maximum Turning travel | 250 mm |

|

|

|

| Turret on the 8 stations mail spindle with Y axis (X, Y, Z axis) |

| Main turret with 8, 9 or 12 stations (X,Z axis) |

| Collet-type pick-up, chuck pick-up integrated into the turret (up to Ø125) |

| Second operations up to 8 power tools (optional) |

|

|

|

| CNC driven tools for turrets |

| Stop and lock of main spindle |

| Stop and lock of pick-up |

| C axis for the main spindle |

|

|

|

| MUPEM (conversational) |

| FAGOR (ISO language - C Axis optional) |

|

|

|