|

|

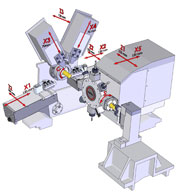

| WIN2 SERIES - STURDINESS AND PRODUCTIVITY |

The new WIN2 series is one of the most sturdy lathes for screw cutting. It can be ordered with bar passage up to Ø100 for pipe or Ø80 for solid bar, which is the limit barloaders in the market can offer.

Among the options provided, highlights the main turret up to 12 stations VDI-30 with driven motorised tools and chuck pick-up up to Ø125, built into the main turret.

New WIN2 series equip linear guides with ball recirculation in all axes and CNC proportional hydraulic drives with feedback from optical scales with a precision of 1 micron. This is how so compact, precise and powerful slides can be achieved.

|

| |

|

|

| Bar Passage with DIN 6343 collet (mm) | Ø42 | Ø60 (65) | Ø80 | Ø100 |

| Main spindle motor: Asynchronous vectorial | 11-15 kW | 15-18 kW | 18-22 kW |

| Maximum spindle speed (RPM) | 4.500 | 3.500 | 3.000 | 2.000 |

|

|

|

| 2 vertical transverse slides (X. Z axis optional) |

| Main turret with 8, 9 or 12 stations (X,Z axis) |

| Collet-type pick-up, chuck pick-up integrated into the turret (up to Ø125) |

| Second operations up to 8 power tools (optional) |

|

|

|

| CNC driven tools for the main turret and second operations |

| Stop and lock of main spindle |

| Stop and lock of pick-up |

| C axis for the main spindle |

|

|

|

| MUPEM (conversational) |

| FAGOR (ISO language - C Axis optional) |

|

|

|