|

|

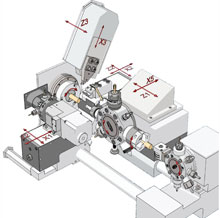

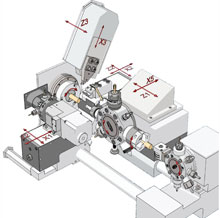

| TWIN - THE ULTIMATE TURNING AND MILLING CENTRE |

TWIN maximizes the capabilities of the WIN model for materials where plongee profiling cannot be used, parts with cross drills and threads and parts with cross and front milling.

An 8-station turret is mounted on the front cross slide with live tool capability.

|

| |

|

|

| Bar Passage with DIN 6343 collet (mm) | Ø30 | Ø42 | Ø60 (65) | Ø80 |

| Main spindle motor: Asynchronous vectorial: | 7,5-11 kW | 11-15 kW |

| Maximum spindle speed (RPM) | 6.000 | 4.500 | 3.000 | 2.500 |

| Maximum Turning travel | 230 mm |

|

|

|

| 2 horizontal transverse slides (X,Z axes) |

| 1 vertical transverse slide (X axis. Z optional) |

| Bidirectional CNC main turret with 8 stations VDI-30 with through-tool cooling (Z axis. X optional) |

| CNC driven tools 2,9 kW (optional) |

| Bidirectional auxiliary CNC turret with 8 stations VDI-20 with through-tool cooling (on the front slide) |

| Driven tools CNC auxiliary turret 2,9 kW (optional) |

| Pick-up for second operations (optional) |

| Second operations with 4 fixed tools or 8 motorised stations turret VDI-20 (optional) |

|

|

|

| C axis for the main spindle |

| Stop and lock of main spindle |

| Stop and lock of pick-up |

| Transverse drilling/ milling/ tapping device |

| Polygon turning/ thread milling device |

|

|

|

| MUPEM (conversational) |

| FAGOR (ISO language - C Axis optional) |

|

|

|