|

|

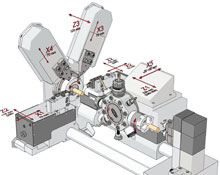

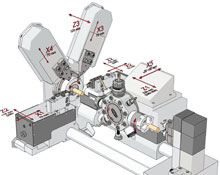

| WIN - THE ULTIMATE TURNING AND MILLING CENTRE |

The WIN machine is one of the most versatile lathes in the world of screw cutting. Its bar capacity and sturdiness of its construction allow to achive the machining of hard materials, while the CNC hydraulic proportional with optical feedback by optical scales (precision 1 micron) makes the accuracy of performance last long, without affecting the force of thrust.

WIN is very adaptable to short series through the conversational programming language and the possibility of using conventional turning tools, turning by interpolation with all its slides.

|

| |

|

|

| Bar Passage with DIN 6343 collet (mm) | Ø30 | Ø42 | Ø60 (65) | Ø80 |

| Main spindle motor: Asynchronous vectorial: | 7,5-11 kW | 11-15 kW |

| Maximum spindle speed (RPM) | 6.000 | 4.500 | 3.000 | 2.500 |

| Maximum Turning travel | 230 mm |

|

|

|

| 2 horizontal transverse slides (X,Z axes) |

| 2 vertical transverse slides (X. Z axis optional) |

| Bidirectional CNC main turret with 8 stations VDI-30 with through-tool cooling (Z axis. X) (optional) |

| CNC driven tools 2,9 kW (optional) |

| Pick-up for second operations (optional) |

| Second operations with 4 fixed tools, turret with 8 motorised stations VDI-20 (optional) |

|

|

|

| C axis for the main spindle |

| Stop and lock of main spindle |

| Stop and lock of pick-up |

| Transverse drilling/ milling/ tapping device |

| Polygon turning/ thread milling device |

|

|

|

| MUPEM (conversational) |

| FAGOR (ISO language - C Axis optional) |

|

|

|